Using Punahou’s 3D printers, faculty and staff have produced 1,300 reusable N95 masks, face shields and other equipment for local hospitals, clinics and outreach groups since mid-March.

Faculty and staff rose to the challenge to address the shortage of personal protective gear for health care workers.

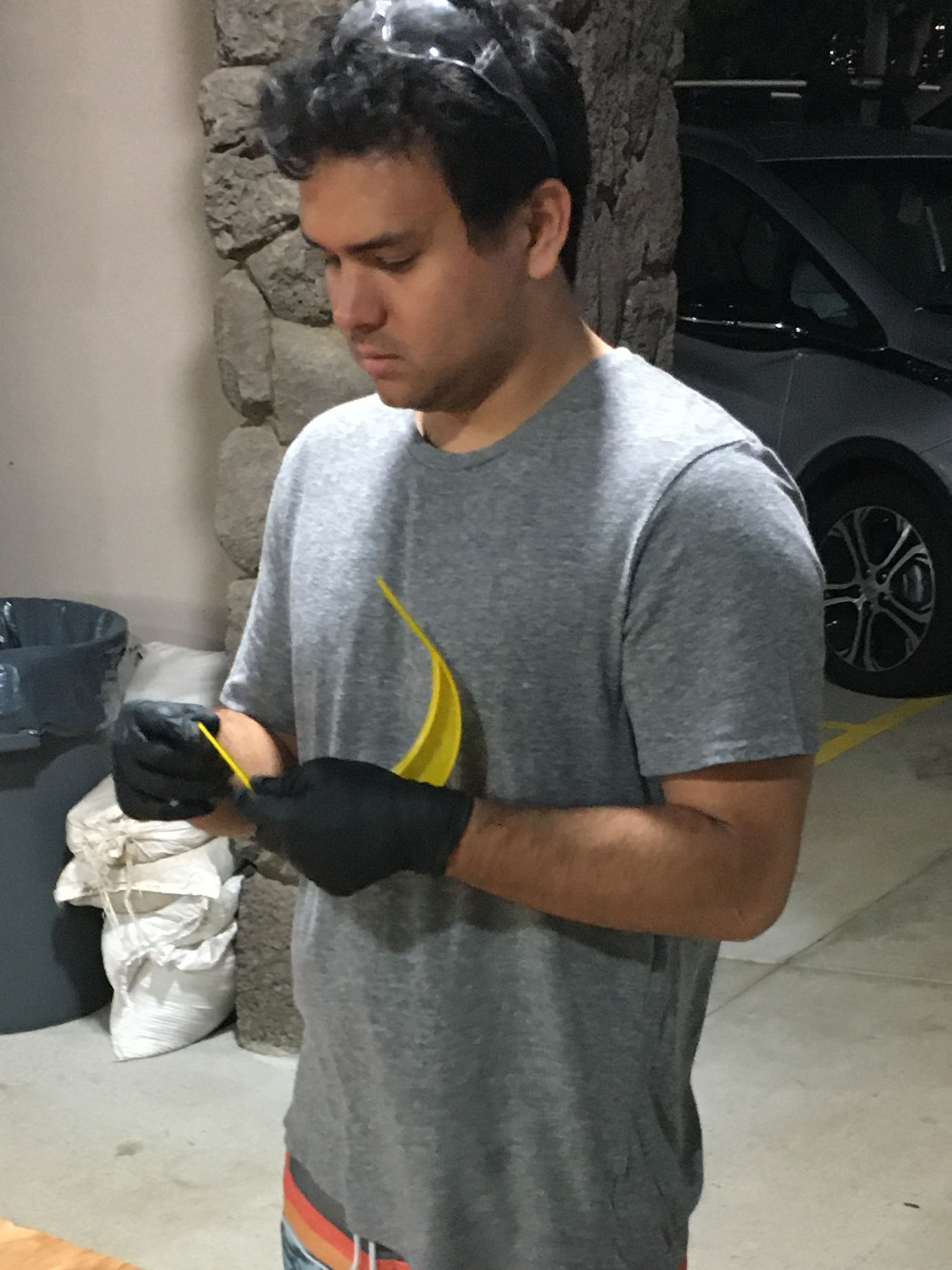

Taryn Loveman, director of Punahou’s Design Technology and Engineering department, and Design Technology Advisor Bobby Izuta ’09 optimized the D. Kenneth Richardson ’48 Learning Lab, the Mau/Stone Design and Engineering Lab and other labs on campus – originally set up for single one-off designs – for mass production. With raw materials sourced and designs tested in hospitals and refined, the group was equipped to produce 22 masks every four to five hours on the 3D printers, which is about 50 to 60 items per day, Loveman said.

The team’s plan was to produce equipment until the medical supply industry could catch up with demand. As major hospitals have started to receive more supplies as of late-April, the Punahou design faculty have shifted their focus to helping a selected handful of smaller clinics and outreach groups.

“We are continuing to do everything we can to use our facilities to help our community,” Loveman shared.

In addition to tackling the shortage of PPE, Izuta is working to address the ventilator shortage. He recently submitted a design for an affordable and easily manufactured ventilator to engineers and the medical community, as part of a design challenge put out by the U.S. Department of Defense.

Kudos to the dedicated faculty, staff and parent volunteers and donors whose efforts have made this project possible.